- #1

blixel

- 52

- 1

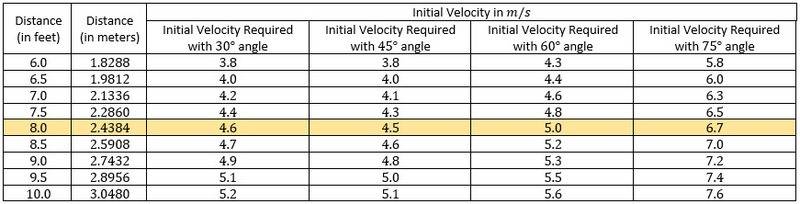

I'm working on a little ball launcher project where I have to launch a tennis ball 6 to 10 feet. (No more, no less.) I made a spreadsheet to help me quickly try different distance values at different angles. (I know 45 degrees is optimal, but I wanted the flexibility of trying different angles.) The spreadsheet helps me find the required initial velocity. Here are the values I came up with for the required initial velocity:

The design I'm using is essentially a crossbow. The ball will be placed in a chair. The chair will be pulled back by a spring that, when released, will accelerate the ball up an incline and lob it the required distance.

My question is... how do I use what I know (which is the initial velocity required) to calculate the required force constant of a spring? And from there, how do I calculate how far back the spring needs to be pulled? And finally, how do I then determine what kind of motor I need which will have enough torque to be able to pull back the spring?

The design I'm using is essentially a crossbow. The ball will be placed in a chair. The chair will be pulled back by a spring that, when released, will accelerate the ball up an incline and lob it the required distance.

My question is... how do I use what I know (which is the initial velocity required) to calculate the required force constant of a spring? And from there, how do I calculate how far back the spring needs to be pulled? And finally, how do I then determine what kind of motor I need which will have enough torque to be able to pull back the spring?

Last edited: