- #1

roro36

- 27

- 1

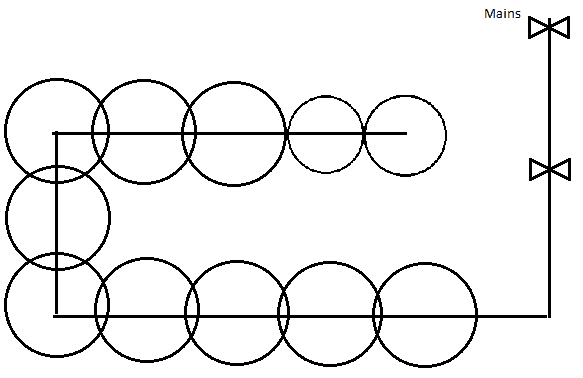

A question was posed to me with the following diagram. http://imgur.com/6ltYKd5

11 Sprinklers, in series with identical heads, but 10 and 11 displaying a much smaller spray pattern.

1. Is this possible, and under what circumstances.

2. What would a good solution be to prevent this?

My thoughts:

1. Not sure if it is actually possible, to occur. I understand it is something to do with pressure vs flow. I would think that the pipe would fill with water to system pressure and all of the heads should be reduced. My other thought is that as it might be completely theoretical and not based in practice, that the reduction in pressure after each sprinkler due to losses, results in the system pressure being reduced at the end (but surely the pipe would fill up and be at 1 pressure. So perhaps a flow problem, which I would think would affect them all equally?

2. 2 solutions I had were to extend the end to below the second valve so there is a sort of ring circuit. If that won't work, I would add another valve and split the sprinklers in the middle. 1 at time operation, i.e. 5 and then 6 or vice-versa.

Question has been bothering me since it was posed. Can't wrap my head around it. Thanks for any help.

11 Sprinklers, in series with identical heads, but 10 and 11 displaying a much smaller spray pattern.

1. Is this possible, and under what circumstances.

2. What would a good solution be to prevent this?

My thoughts:

1. Not sure if it is actually possible, to occur. I understand it is something to do with pressure vs flow. I would think that the pipe would fill with water to system pressure and all of the heads should be reduced. My other thought is that as it might be completely theoretical and not based in practice, that the reduction in pressure after each sprinkler due to losses, results in the system pressure being reduced at the end (but surely the pipe would fill up and be at 1 pressure. So perhaps a flow problem, which I would think would affect them all equally?

2. 2 solutions I had were to extend the end to below the second valve so there is a sort of ring circuit. If that won't work, I would add another valve and split the sprinklers in the middle. 1 at time operation, i.e. 5 and then 6 or vice-versa.

Question has been bothering me since it was posed. Can't wrap my head around it. Thanks for any help.