- #1

PainterGuy

- 940

- 69

- TL;DR Summary

- I'm having trouble applying the Fleming's right hand rule in a static magnetic field of four poles. I just wanted to know the direction of induced current in both sides of coil.

Hi,

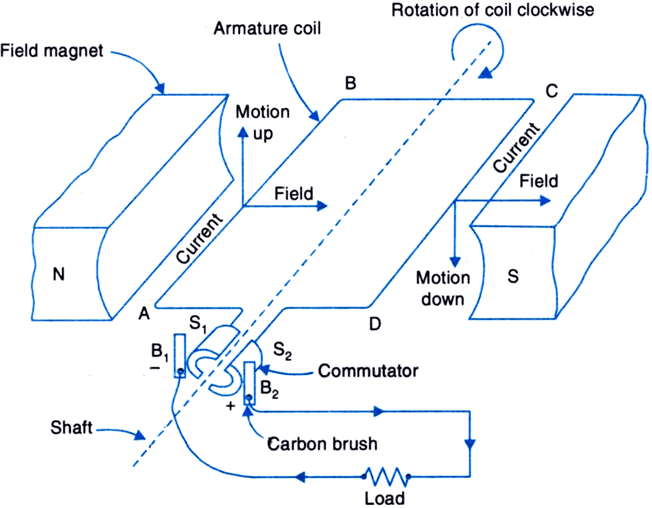

The picture below shows a DC generator. The magnetic field is uniform. As the coil rotates clockwise, the right side of coil is moving downward and the left side of coil moves upward. Using Fleming's right hand rule, one can deduce the direction of conventional current in both sides of coil. In the right hand side, the current is coming out of page and in the left hand side of coil the current is running into the page. It would produce pulsating DC voltage.

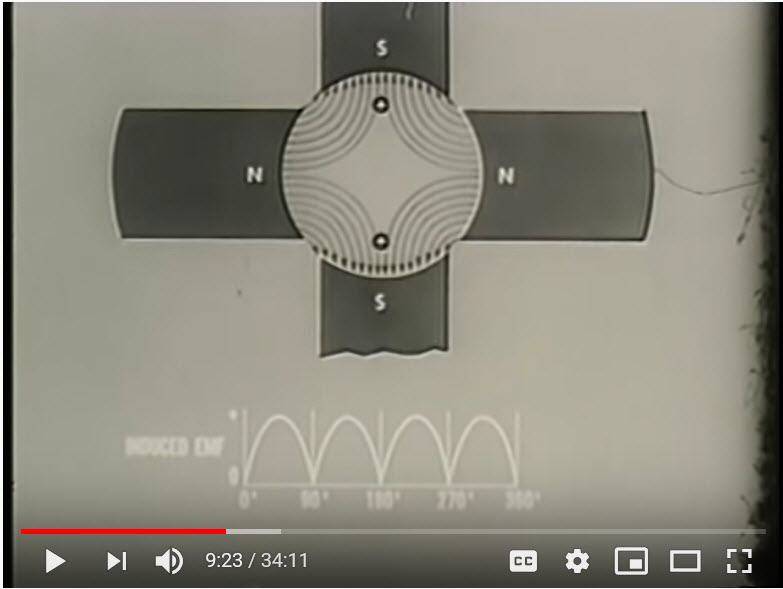

Now suppose that the same coil is being rotated in the same direction, i.e. clockwise, using four magnetic poles as shown below. How is the right hand rule applied in such a case? Is there any possibility that the rule could just be applied without doing the calculation? Will the upper side of coil have current going into the page and in the lower side coming out of the page? Thank you!

Source: ("/watch?v=OpL0joqJmqY" insert "youtube.com" in front )

The picture below shows a DC generator. The magnetic field is uniform. As the coil rotates clockwise, the right side of coil is moving downward and the left side of coil moves upward. Using Fleming's right hand rule, one can deduce the direction of conventional current in both sides of coil. In the right hand side, the current is coming out of page and in the left hand side of coil the current is running into the page. It would produce pulsating DC voltage.

Now suppose that the same coil is being rotated in the same direction, i.e. clockwise, using four magnetic poles as shown below. How is the right hand rule applied in such a case? Is there any possibility that the rule could just be applied without doing the calculation? Will the upper side of coil have current going into the page and in the lower side coming out of the page? Thank you!

Source: ("/watch?v=OpL0joqJmqY" insert "youtube.com" in front )