- #1

raionz

- 1

- 0

My boss just told me to get him this today and the last time I took a mechanic class pluto was still a planet.

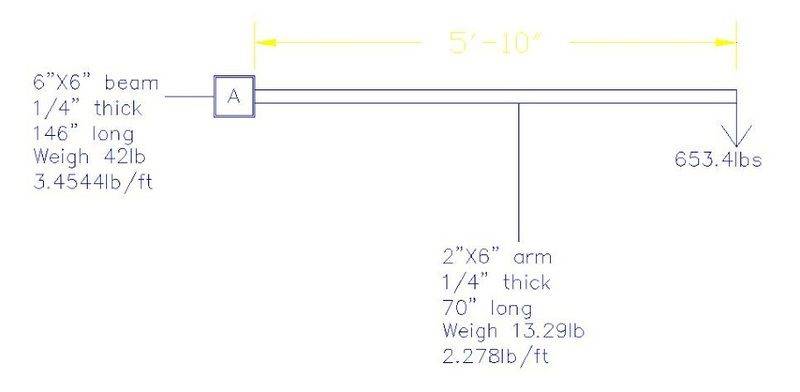

See diagram attached.

Both bulkhead A and arm are made of aluminum T6061 hollow tubes.

Arm is at center of A.

Assuming that arm will never break off from A, will the current load deform A? I vaguely remember max torsional moments is what I'm looking for but that doesn't take into account material strength.

Shear stress = load + weight of arm.

t=0.25"

b=6"

If max torsional moment is = (2/9) (tau max) (b^3)

tau max = 0.27 (V/t)[b^3-(b-2t)^3] / [b^4 - (b-2t)^4]

V = transverse shear force

is V = shear stress?

Where does material property come in? Please help. Thanks

See diagram attached.

Both bulkhead A and arm are made of aluminum T6061 hollow tubes.

Arm is at center of A.

Assuming that arm will never break off from A, will the current load deform A? I vaguely remember max torsional moments is what I'm looking for but that doesn't take into account material strength.

Shear stress = load + weight of arm.

t=0.25"

b=6"

If max torsional moment is = (2/9) (tau max) (b^3)

tau max = 0.27 (V/t)[b^3-(b-2t)^3] / [b^4 - (b-2t)^4]

V = transverse shear force

is V = shear stress?

Where does material property come in? Please help. Thanks