- #1

Pir4t3x

- 9

- 0

Hello,

I'm having a question regarding the sensors and the techniques in fluid mechanics. Since my skills are amazing in this field, here I'm asking

you questions xD

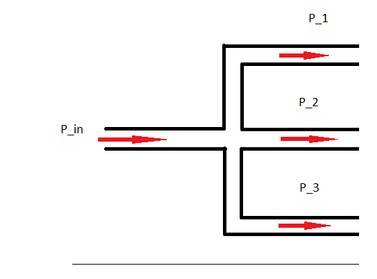

I want to measure the air pressure of this tube/pipe (P1,P2,P3). This pipe will be flushed with water and then with compressed air.

In principle, it should be just pressure sensor in each pipe and problem solved!

The question is that if I want to use a pressure sensor which doesn't have water resistantce. I'll measure the air pressure only when the

compressed air is flushed. How can I protect the sensor from water during the water flushing step?

Note: I was thinking of adding valve to protect the pressure sensor (close it when the water is flusing) but the idea would be not practical. As

any drop of water left in the pipe would damage the sensor (if there is blockage for example).

I have been thinking about this for too long and it seems impossible not to use water resistant sensor. Is there any chance to do it?

I hope that I can find my answer here.

I'm having a question regarding the sensors and the techniques in fluid mechanics. Since my skills are amazing in this field, here I'm asking

you questions xD

I want to measure the air pressure of this tube/pipe (P1,P2,P3). This pipe will be flushed with water and then with compressed air.

In principle, it should be just pressure sensor in each pipe and problem solved!

The question is that if I want to use a pressure sensor which doesn't have water resistantce. I'll measure the air pressure only when the

compressed air is flushed. How can I protect the sensor from water during the water flushing step?

Note: I was thinking of adding valve to protect the pressure sensor (close it when the water is flusing) but the idea would be not practical. As

any drop of water left in the pipe would damage the sensor (if there is blockage for example).

I have been thinking about this for too long and it seems impossible not to use water resistant sensor. Is there any chance to do it?

I hope that I can find my answer here.