- #1

Kaarmugilan

- 1

- 0

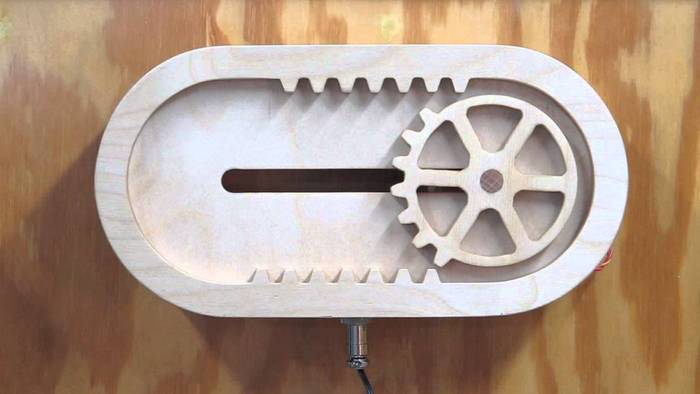

I am planning to design a reciprocating rack and pinion, as shown in this figure

I plan to attach a cutter to this setup to cut anything.I need to know how to calculate the motor specifications for the given mass of the gear, cutter and cutter velocity

I plan to make it with a plywood

I plan to attach a cutter to this setup to cut anything.I need to know how to calculate the motor specifications for the given mass of the gear, cutter and cutter velocity

I plan to make it with a plywood