- #1

MechEng2023

- 3

- 1

- TL;DR Summary

- In a mechanical system consisting of an air cylinder, linkage, and shaft, i'm trying to understand if changing the cylinder applied force will impact the radial force that exists between linkage and shaft.

Hello,

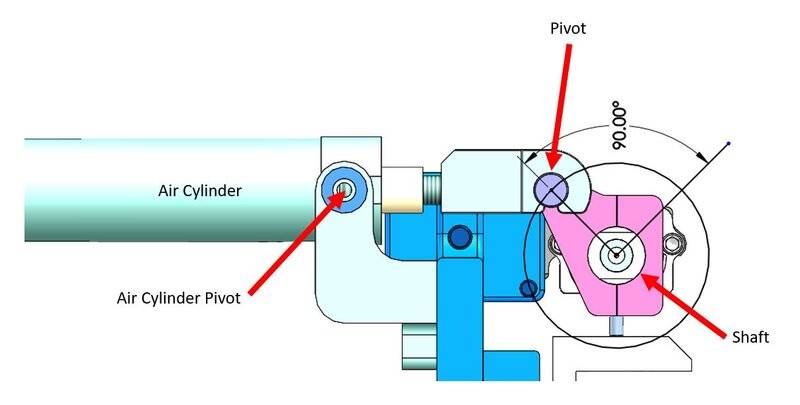

For the mechanical system below, i'm trying to understand the relationship between cylinder applied force and radial force.

The system consists of a shaft which is held in-place by a bushing. The shaft is connected to an air cylinder via a linkage. The air cylinder is on a fixed pivot and has an internal hard stop in both extended and retracted positions. Actuating the air cylinder between its extended and retracted positions rotates the shaft between 2 positions that are 90deg apart. The shaft doesn't rotate freely within the bushing - significant friction between the shaft and bushing exists.

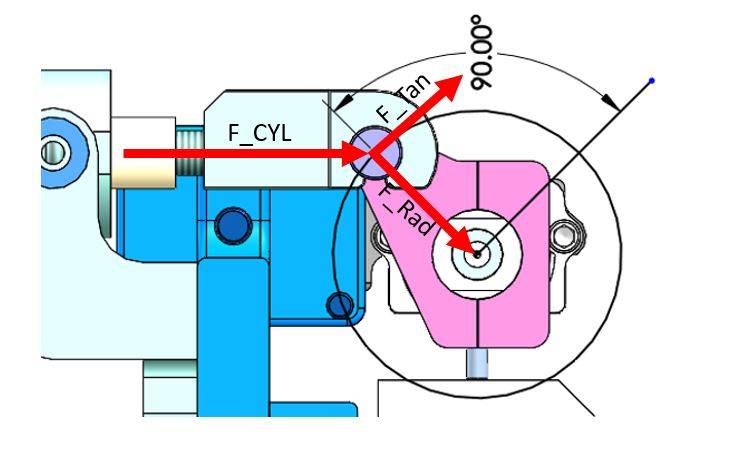

I'm in the process of analyzing the radial force that the linkage will transfer to the shaft, using force triangles drawn at various positions throughout the shaft's 90deg rotation. What i'm struggling to understand is whether or not increasing the cylinder's applied force will result in an increase in the radial force that the linkage transfers to the shaft (The system's geometry and friction between shaft and bushing remain constant. The only variable changing is the cylinder's applied force)

For example, assume that 10 lbf and 10,000 lbf applied cylinder force are both enough to overcome friction and cause the shaft to rotate. Will the 10,000 lbf cylinder force result in a higher radial force being transferred from linkage to shaft? OR, does the system only generate enough force to overcome friction, and since friction is constant in this scenario, a 10lbf and 10,000 lbf cylinder applied force will result in identical radial forces being transferred from linkage to shaft?

Any insight is appreciated.

Thank you!

For the mechanical system below, i'm trying to understand the relationship between cylinder applied force and radial force.

The system consists of a shaft which is held in-place by a bushing. The shaft is connected to an air cylinder via a linkage. The air cylinder is on a fixed pivot and has an internal hard stop in both extended and retracted positions. Actuating the air cylinder between its extended and retracted positions rotates the shaft between 2 positions that are 90deg apart. The shaft doesn't rotate freely within the bushing - significant friction between the shaft and bushing exists.

I'm in the process of analyzing the radial force that the linkage will transfer to the shaft, using force triangles drawn at various positions throughout the shaft's 90deg rotation. What i'm struggling to understand is whether or not increasing the cylinder's applied force will result in an increase in the radial force that the linkage transfers to the shaft (The system's geometry and friction between shaft and bushing remain constant. The only variable changing is the cylinder's applied force)

For example, assume that 10 lbf and 10,000 lbf applied cylinder force are both enough to overcome friction and cause the shaft to rotate. Will the 10,000 lbf cylinder force result in a higher radial force being transferred from linkage to shaft? OR, does the system only generate enough force to overcome friction, and since friction is constant in this scenario, a 10lbf and 10,000 lbf cylinder applied force will result in identical radial forces being transferred from linkage to shaft?

Any insight is appreciated.

Thank you!

Last edited by a moderator: