- #1

k.udhay

- 160

- 10

Hello all,

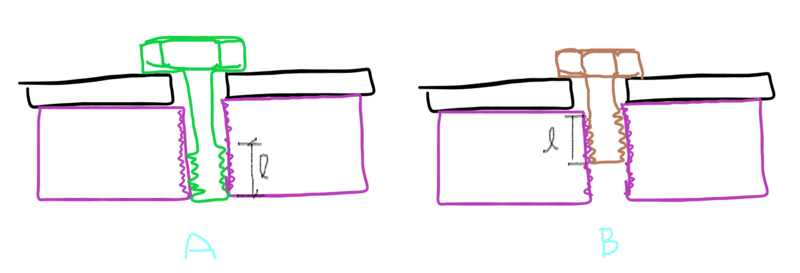

In a recent discussion, I came across this question of influence of free length (or unthreaded length) in bolts in retaining the clamping force between the elements to be joined. Out of the two proposals in the attached pic., which one will keep the two plates clamped for a longer time:

Here are some assumptions:

1. Materials of respective parts are same in both A and B

2. Diameters of the two bolts at comparable locations are also same

3. Torque given to tighten the bolts are also same

4. Length of thread engagement is also same

Pl. let me know your views. Thanks.

In a recent discussion, I came across this question of influence of free length (or unthreaded length) in bolts in retaining the clamping force between the elements to be joined. Out of the two proposals in the attached pic., which one will keep the two plates clamped for a longer time:

Here are some assumptions:

1. Materials of respective parts are same in both A and B

2. Diameters of the two bolts at comparable locations are also same

3. Torque given to tighten the bolts are also same

4. Length of thread engagement is also same

Pl. let me know your views. Thanks.