- #1

carlos468

- 20

- 2

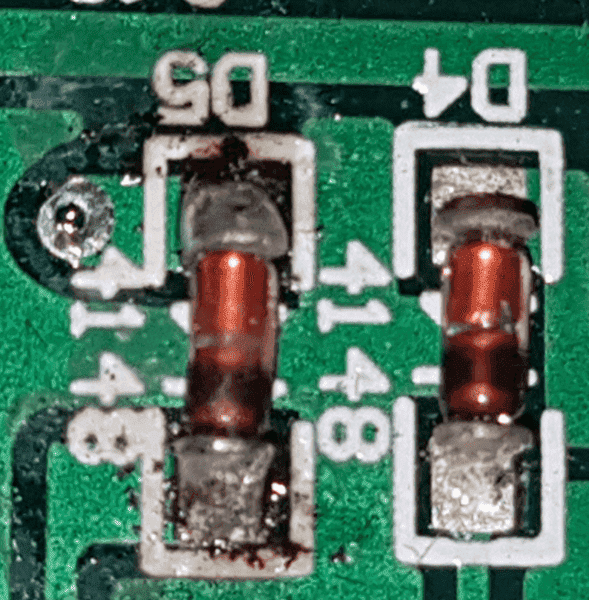

Could someone please help me identify this and how to test it

it is inside a soundbar that someone brought to me to look at as sound was only coming out of one side everything else looks ok apart for these or at least one doesn't look good and has some heat marks.

any help would be appreciated.

it is inside a soundbar that someone brought to me to look at as sound was only coming out of one side everything else looks ok apart for these or at least one doesn't look good and has some heat marks.

any help would be appreciated.

Attachments

Last edited by a moderator: