- #1

kal854

- 13

- 0

Problem statement:

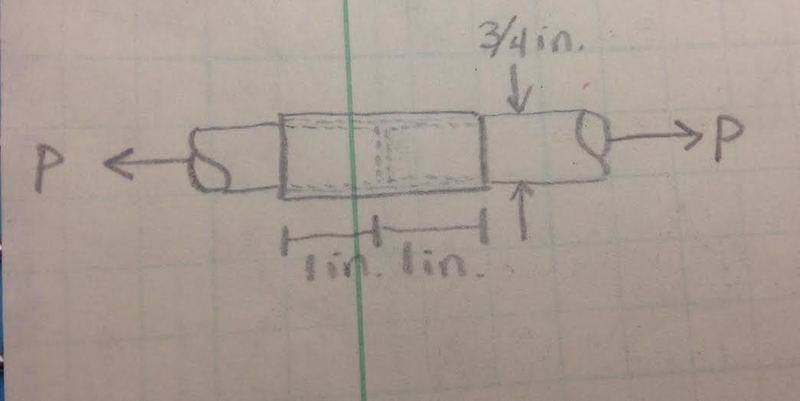

Two 3/4-in.-diameter nylon rods are spliced together by gluing a 2-in. section of plastic pipe over the rod ends, as shown in the figure. If a tensile force of P = 500 lb is applied to the spliced nylon rod, what is the average shear stress in the glue going between the pipe and rods?

Figure:

I need help with this problem. I know that {average shear stress} = {force} / {area}. But I am very confused when you take into account this splicing! Thank you in advance!

Two 3/4-in.-diameter nylon rods are spliced together by gluing a 2-in. section of plastic pipe over the rod ends, as shown in the figure. If a tensile force of P = 500 lb is applied to the spliced nylon rod, what is the average shear stress in the glue going between the pipe and rods?

Figure:

I need help with this problem. I know that {average shear stress} = {force} / {area}. But I am very confused when you take into account this splicing! Thank you in advance!