- #1

Mech_LS24

- 148

- 16

- TL;DR Summary

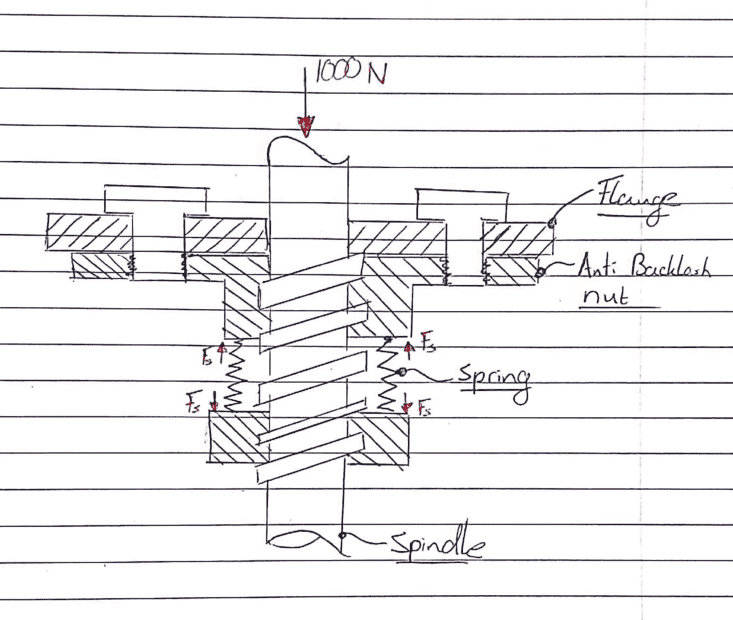

- Forces with FBD diagram. I want to know how to calculate the backlash if the a force applied on the spindle is known

Hi,

On the internet I have seen "anti backlash nuts" Anti backlash nut example (see image), I searched on the forum but couldn't find any related topics. But it has made me interested how this should be considered as there is (in my opinion) another force namely, the Force occurred due to the spring (Fs). I made a FBD of the backlash nut connected with a spindle and a flange? How can be calculated how strong this spring should be if a force of 1000 N is applied to the spindle which should lead to a minimum backlash? How to determine the backlash after calculating the force on the spring?

On the internet I have seen "anti backlash nuts" Anti backlash nut example (see image), I searched on the forum but couldn't find any related topics. But it has made me interested how this should be considered as there is (in my opinion) another force namely, the Force occurred due to the spring (Fs). I made a FBD of the backlash nut connected with a spindle and a flange? How can be calculated how strong this spring should be if a force of 1000 N is applied to the spindle which should lead to a minimum backlash? How to determine the backlash after calculating the force on the spring?