- #1

Bikkehaug

- 6

- 0

Hello

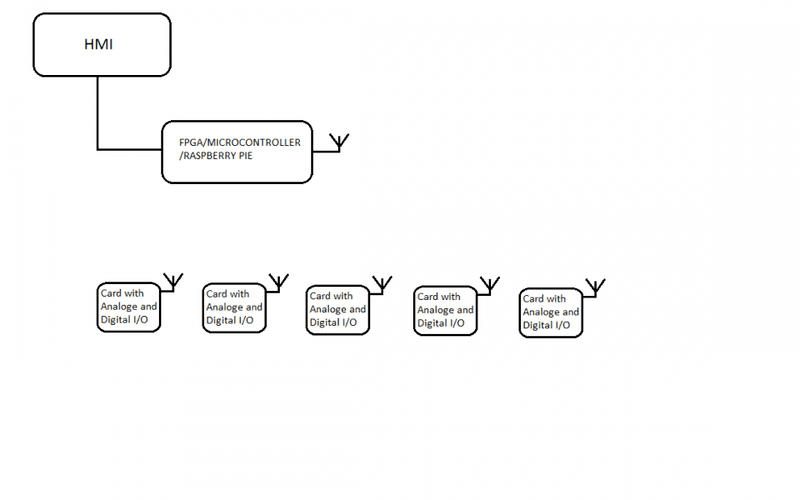

I want to make a HMI that monitors i/o through a microcontroller/fpga/something.

The problem I've come across is to figure out what's going to interpret/read i/o at the end of this system. For what it's worth, it's going to read i/o from "props" used in so called Escape Rooms - so they need to be fairly small and support wireless communication (bluetooth, xbee, Zigbee or something).

Essentially, these cards in my sketch, all they need to do is send i/o information wirelessly to the microcontroller.

For instance, I have a prop where a button has to be pressed in order for it to be solved. My goal is to send a signal to the microcontroller that the correct button has been pressed, and then display this on the HMI (windows forms application will be used for this).

Any ideas for what to use as a "card"? Keeping in mind price, size and wireless strength.

Thanks.

I want to make a HMI that monitors i/o through a microcontroller/fpga/something.

The problem I've come across is to figure out what's going to interpret/read i/o at the end of this system. For what it's worth, it's going to read i/o from "props" used in so called Escape Rooms - so they need to be fairly small and support wireless communication (bluetooth, xbee, Zigbee or something).

Essentially, these cards in my sketch, all they need to do is send i/o information wirelessly to the microcontroller.

For instance, I have a prop where a button has to be pressed in order for it to be solved. My goal is to send a signal to the microcontroller that the correct button has been pressed, and then display this on the HMI (windows forms application will be used for this).

Any ideas for what to use as a "card"? Keeping in mind price, size and wireless strength.

Thanks.