- #1

theBEAST

- 364

- 0

So I know that head is related to energy. And it is just another way to measure the energy at any given point in the flow (although in units of meters/feet/etc). So does that mean the head is equal at all points of a pipe? Since by conservation of energy and mass, and assuming the flow is steady, then the energy everywhere in the particles must be the same?

Also for NPSH (net positive suction head). It is defined as the head required at pump inlet to prevent cavitation:

NPSH = Pi/(ρg) + Vi2/(2g) - Pv/(ρg)

There are two types of NPSH, one is NPSH actual and one is NPSH required. Mathematically how are these different? Do they both follow the same equation above? If so, why would they be different?

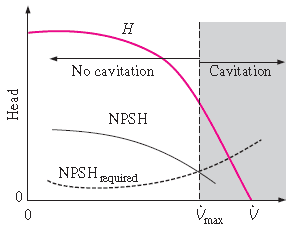

See in this plot:

NPSH actual is always larger than NPSH required, why is this?

This was a topic that the professor quickly covered and I don't think we will be tested on it. But out of curiosity I really want to understand the concepts behind it. If anyone could help me it would be greatly appreciated.

Also for NPSH (net positive suction head). It is defined as the head required at pump inlet to prevent cavitation:

NPSH = Pi/(ρg) + Vi2/(2g) - Pv/(ρg)

There are two types of NPSH, one is NPSH actual and one is NPSH required. Mathematically how are these different? Do they both follow the same equation above? If so, why would they be different?

See in this plot:

NPSH actual is always larger than NPSH required, why is this?

This was a topic that the professor quickly covered and I don't think we will be tested on it. But out of curiosity I really want to understand the concepts behind it. If anyone could help me it would be greatly appreciated.