- #1

bluecap

- 396

- 13

Hello.. (see 3 colored pictures below to illustrate the question)

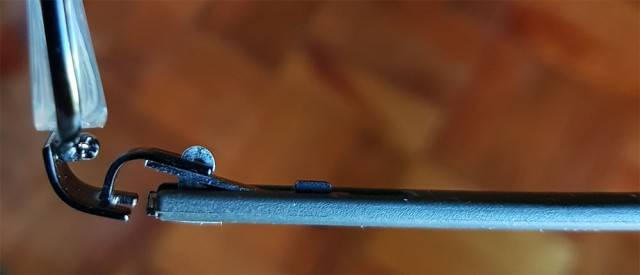

I have a pair of eyeglasses with screwless spring hinges that uses spring steel metal strip (see full pictures below). I’d like to understand something about it. When the temples are fully opened.. the spring metal strip are in bend position (see first picture).. when I close the temples.. the spring metal strip are more flat (see last picture).. what I’d like to know is.. how many times or how many cycles between closing and opening the temples can the spring steel metal flat strip just crack or fracture? Anyone seen other eyeglasses like this? It's branded Thomo (not the expensive Ray Ban). I know my mistake was not choosing just the simple screw type hinges without worrying someday the spring metal strip can just fracture from fatigue. Usually how many cycles before this fatigues, any ideas? Thank you.

temple open.. spring steel metal strip bend

following shows temple closed.. spring steel metal string flat

How many times of closing and opening the temples before the spring steel metal strips cracks?

For the math wiz.. how do you compute it?

I have a pair of eyeglasses with screwless spring hinges that uses spring steel metal strip (see full pictures below). I’d like to understand something about it. When the temples are fully opened.. the spring metal strip are in bend position (see first picture).. when I close the temples.. the spring metal strip are more flat (see last picture).. what I’d like to know is.. how many times or how many cycles between closing and opening the temples can the spring steel metal flat strip just crack or fracture? Anyone seen other eyeglasses like this? It's branded Thomo (not the expensive Ray Ban). I know my mistake was not choosing just the simple screw type hinges without worrying someday the spring metal strip can just fracture from fatigue. Usually how many cycles before this fatigues, any ideas? Thank you.

temple open.. spring steel metal strip bend

following shows temple closed.. spring steel metal string flat

How many times of closing and opening the temples before the spring steel metal strips cracks?

For the math wiz.. how do you compute it?