- #1

mooseboi

- 6

- 0

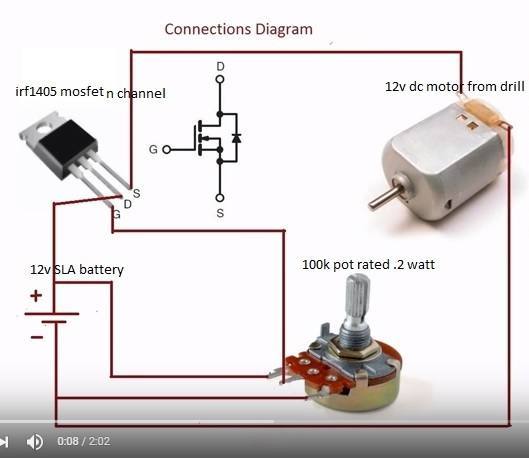

Hello all, I am trying to create a circuit that allows me to use serial data to control the speed of a 12v dc motor I removed from an electric drill. So far I have successfully made the circuit in diagram (a) using a 100k pot to alter the speed. So the next problem to solve is how I can instead use serial data as the controller.

Diagram (a)

Diagram (b)

Now, the creator of the circuit depicted in diagram (b) stated "I suppose with really beefy motors and really beefy motor power supplies, there might be some danger of getting the backEMF spikes onto the motherboard, causing problems, so ... don't do that." However, someone suggested using diodes to solve this problem of backEMF to protect the computer from spikes. So with all this information considered, my question is now this: What modifications need to be made to the circuit in diagram (b) to make it safe to use so to avoid any nasty backEMF and other potential harm to my computer when using serial data to control the MOSFET?

Many thanks,

Sam.

Diagram (a)

Diagram (b)

Now, the creator of the circuit depicted in diagram (b) stated "I suppose with really beefy motors and really beefy motor power supplies, there might be some danger of getting the backEMF spikes onto the motherboard, causing problems, so ... don't do that." However, someone suggested using diodes to solve this problem of backEMF to protect the computer from spikes. So with all this information considered, my question is now this: What modifications need to be made to the circuit in diagram (b) to make it safe to use so to avoid any nasty backEMF and other potential harm to my computer when using serial data to control the MOSFET?

Many thanks,

Sam.

Last edited: