- #1

Mikealvarado100

- 55

- 0

Hi

What happens when a centrifugal pump rotate inversely? Does it add Head to fluid?

What happens when a centrifugal pump rotate inversely? Does it add Head to fluid?

For radial blades and a symmetric casing, it wouldn't make a difference which way it turns. For curved blades and asymmetric casing the below comparison of forward vs backward curved blades might help (around 4:00):Mikealvarado100 said:What happens when a centrifugal pump rotate inversely?

David Lewis said:When the direction of rotation of the impeller reverses then the flow is also reversed

Just to make sure it is clear though; an awful lot of pumps (like the one pictured on the YouTube video cover) don't have symmetrical casings, they have an outlet on one side or the other. For those, if you spin them backwards, it has a huge impact on performance.A.T. said:For radial blades and a symmetric casing, it wouldn't make a difference which way it turns.

I think you were responding to me...Mikealvarado100 said:A.T.

What do you mean with 'Huge Impact'. More explanation is needed. Does it mean the majority of C.F. pump does not transfer fluid to suction side, if they rotate inversely? Or fluid is transferred but with low efficiency?

Which one?

Another question is which C.F. pumps can rotate inversely without impact mentioned?

Nidum said:I thought that this question was quite well dealt with in your other threads where we discussed the interpretation of this diagram ?

I certainly don't want to be unhelpful but I am having some difficulty in understanding what the problem is .

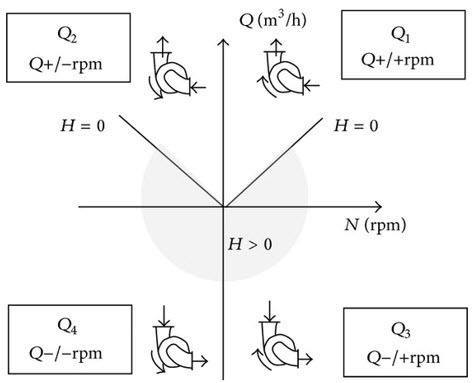

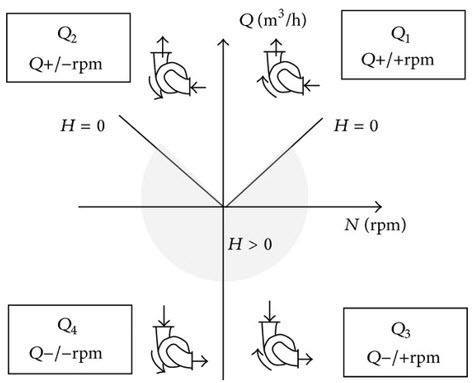

A pump like the one shown in A.T.'s video has the four possible operating conditions shown in the diagram .

Nidum said:I thought that this question was quite well dealt with in your other threads where we discussed the interpretation of this diagram ?

I certainly don't want to be unhelpful but I am having some difficulty in understanding what the problem is .

A pump like the one shown in A.T.'s video has the four possible operating conditions shown in the diagram .

Mikealvarado100 said:I exactly mean which CF pumps works in both direction without huge impacts (huge headloss or decrease in efficiency)?

Mikealvarado100 said:Which pumps can behave as both pump and turbine? It is my own thought that axial flow pumps with symmetric casing can operate as pump and turbine (with normal efficiency).

A reverse rotating pump is a type of pump that uses two impellers rotating in opposite directions to create flow and pressure in a fluid. The impellers are mounted on the same shaft, but their rotation is counter to each other.

A reverse rotating pump works by using the opposing rotations of the two impellers to create a higher differential pressure and flow rate in the fluid. This is achieved by the first impeller accelerating the fluid and the second impeller decelerating it, resulting in an overall increase in energy and pressure.

Yes, a reverse rotating pump does add head to fluid. The opposing rotations of the impellers create a higher pressure and flow rate in the fluid, resulting in an increase in head or height of the fluid column.

The main advantage of using a reverse rotating pump is its ability to add head to fluid, making it useful for applications where high pressures are required. It also has a more compact design compared to traditional pumps and can handle a wide range of viscosities and fluid types.

While reverse rotating pumps have many advantages, they also have some limitations. They are not suitable for handling large solid particles or highly abrasive fluids, and their efficiency can be affected by changes in the fluid viscosity. They also require precise alignment of the impellers to work effectively.