- #1

recreated

- 50

- 1

The equation for heat transfer is:

1. Q = U.A.(TL-T1)

Where:

Q= heat transferred (W).

U= overal h.t. coefficient.

A= area of heat exhanger (m^2).

TL= Temp. of refrigerated space (Kelvin)

T1= Low temp. of refrigerant= refrigerant in evaporator (K)

I want to eventually find the maximum heat removed from the refrigerated space: QL, corresponding to the optimal heat exchanger area ratio: Xa.

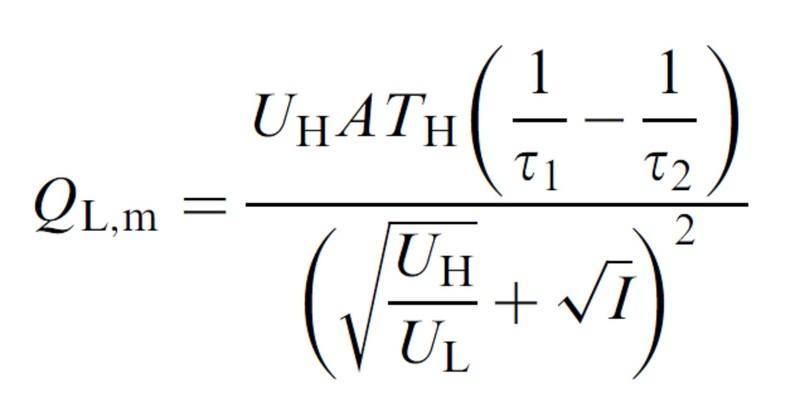

2. QL,max. =

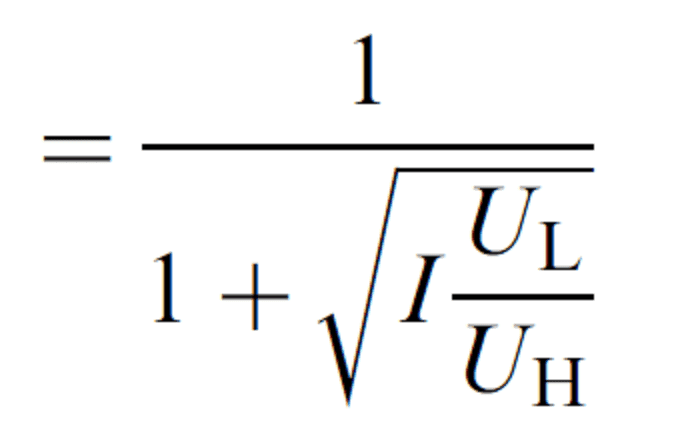

(Click for clear version)3. Xa,optimum =

(Click for clear version)3. Xa,optimum =

I know all values in parts 1. 2. and 3. except for A, U and QL,m(QL max). My question:

I know all values in parts 1. 2. and 3. except for A, U and QL,m(QL max). My question:

I want to find a reasonable value for A and U (the values will be theoretical but must be realistic, and I only need these results so I can show how using a optimised area ratio will improve them). After that I will optimize the system using the QL max and Xa optimum equations, from 2. and 3. above, respectively. Does this make sense to you? I have many doubts, such as when I sub in a reasonable value for A, I do not find a reasonable value for U, even though I trust my other values are correct.

What other equations for U are there, so I might be able to find this oppose to estimate?

Thanks for your time

1. Q = U.A.(TL-T1)

Where:

Q= heat transferred (W).

U= overal h.t. coefficient.

A= area of heat exhanger (m^2).

TL= Temp. of refrigerated space (Kelvin)

T1= Low temp. of refrigerant= refrigerant in evaporator (K)

I want to eventually find the maximum heat removed from the refrigerated space: QL, corresponding to the optimal heat exchanger area ratio: Xa.

2. QL,max. =

I want to find a reasonable value for A and U (the values will be theoretical but must be realistic, and I only need these results so I can show how using a optimised area ratio will improve them). After that I will optimize the system using the QL max and Xa optimum equations, from 2. and 3. above, respectively. Does this make sense to you? I have many doubts, such as when I sub in a reasonable value for A, I do not find a reasonable value for U, even though I trust my other values are correct.

What other equations for U are there, so I might be able to find this oppose to estimate?

Thanks for your time

Last edited: