- #1

jegues

- 1,097

- 3

Hello,

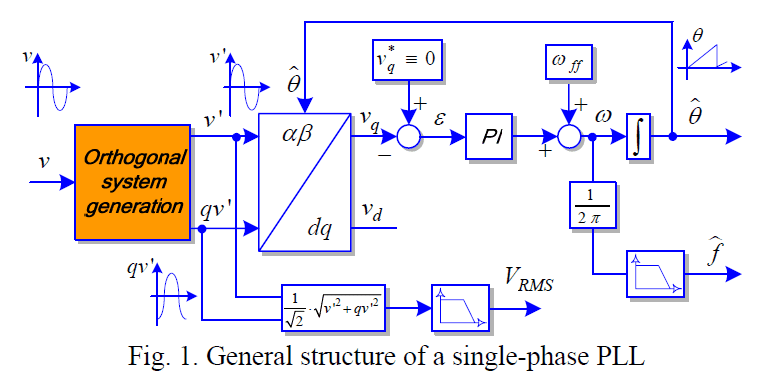

I've written a program that executes the following control diagram.

Now I am trying to calculate the PI controller gains such that I can achieve a settling time of 0.06s and a damping factor of 1.

How can I do this?

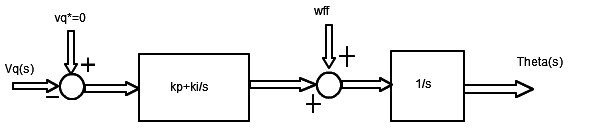

I tried sketching a control diagram of the relevant portions.

Any suggestions/comments/advice would be greatly appreciated.

Thanks!

I've written a program that executes the following control diagram.

Now I am trying to calculate the PI controller gains such that I can achieve a settling time of 0.06s and a damping factor of 1.

How can I do this?

I tried sketching a control diagram of the relevant portions.

Any suggestions/comments/advice would be greatly appreciated.

Thanks!