- #1

jpbussen

- 1

- 0

Hello Everyone. I'm very new to this website and am turning to anyone for help.

I'm trying to design and build a large electromagnet to do some scrap metal lifting for me and my grandpa that can be hooked onto a crane/loader of a tractor/payloader. I'm currently studying electrical and mechanical engineering at a university in Kansas, but I'm only in my second year to have the knowledge to design one correctly. I grew up on a farm and ranch and have all the tools (lathe, drills, mill, MIG welder, TIG Welder, ARC welder, plasma cutter) and abilities I need to do the job correctly because I want to build one tough enough to handle the work.

I know how to build small simple electromagnets, but I'm not sure what I need to do with a larger scale version.

* My intentions are to build one that can hold around 1000lbs to, well roughly a car would be nice, so around 5000lbs.

* Would like to run it off a 12V DC car battery or if needed 24v by hooking two in a series. If making one that can run on 120v or 240v AC current is ideal, than ideas would be appreciated.

* I'm wanting the total diameter to be around the ballpark of 2 feet.

*Use an iron core of anywhere around 2" to 6" in diameter depending on what design is best to go with

What I don't know.

* What is possible

* The Best electromagnet design

* Size of resin wire to be using and wraps

* Do I need an insulator between the iron core and windings

* If I can hook hook it up directly to the battery using a switch/relay to control the on/off or if i need an amperage controller

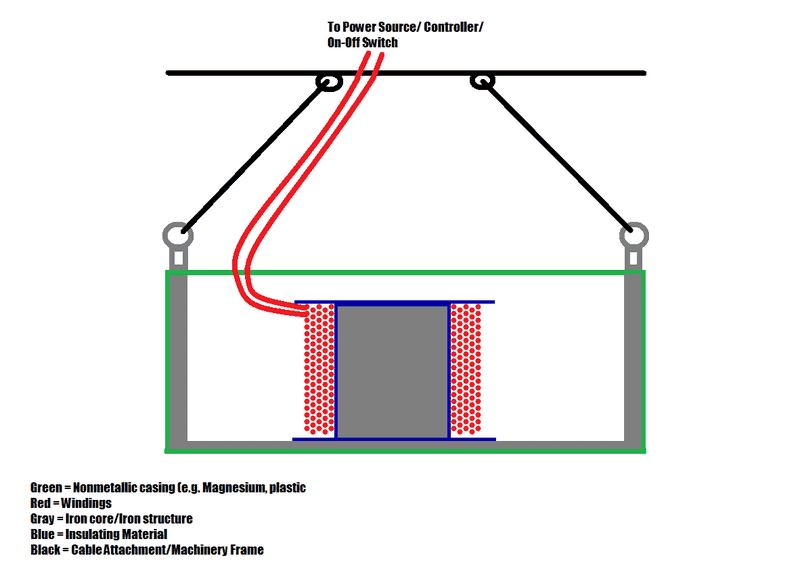

Below is a drawing of what i assumed it would end up being designed to look like\

Thanks for your help

I'm trying to design and build a large electromagnet to do some scrap metal lifting for me and my grandpa that can be hooked onto a crane/loader of a tractor/payloader. I'm currently studying electrical and mechanical engineering at a university in Kansas, but I'm only in my second year to have the knowledge to design one correctly. I grew up on a farm and ranch and have all the tools (lathe, drills, mill, MIG welder, TIG Welder, ARC welder, plasma cutter) and abilities I need to do the job correctly because I want to build one tough enough to handle the work.

I know how to build small simple electromagnets, but I'm not sure what I need to do with a larger scale version.

* My intentions are to build one that can hold around 1000lbs to, well roughly a car would be nice, so around 5000lbs.

* Would like to run it off a 12V DC car battery or if needed 24v by hooking two in a series. If making one that can run on 120v or 240v AC current is ideal, than ideas would be appreciated.

* I'm wanting the total diameter to be around the ballpark of 2 feet.

*Use an iron core of anywhere around 2" to 6" in diameter depending on what design is best to go with

What I don't know.

* What is possible

* The Best electromagnet design

* Size of resin wire to be using and wraps

* Do I need an insulator between the iron core and windings

* If I can hook hook it up directly to the battery using a switch/relay to control the on/off or if i need an amperage controller

Below is a drawing of what i assumed it would end up being designed to look like\

Thanks for your help