- #1

Tadas

- 3

- 0

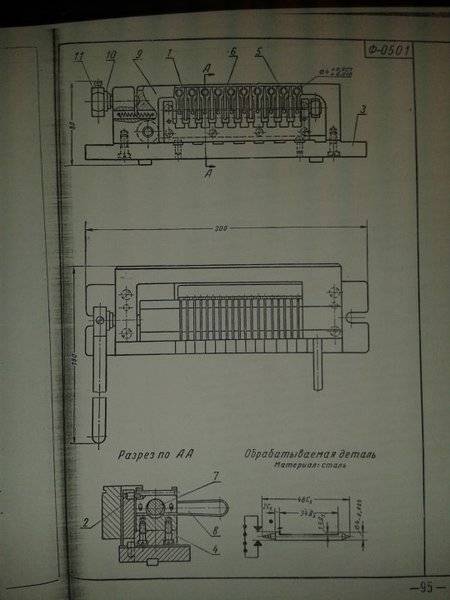

Hello. I am a student and I got a task to design a 3D model for multi-slot holder for round shaped parts for milling operation.

In the picture I attached there is shown a device that I should design, maybe improve it, but the problem is that a drawing is a bit unclear and I can't fully understand it so I couldn't make 3D model. In the bottom of drawing it is a drawing of part that has to be milled.

Maybe you know where I could find a different design (not so ancient) of such holder that would be suitable for given parts and be easier to understand. Or if not could you help me understand this one drawing and help me make 3D model of such device.

Following is translation from Russian language. I am not very good at Russian, nor am I native English speaker so this translation might be hard to understand.

Description of drawing:

This device is for milling groves on 10 cilinder shaped parts at the same time.

Datum of part is established by outer surface that is inserted into 10 special changs (not sure how to translate the word) holes 1. These changs also are device fixing elements. As an extra datum point serves support 2. Device consist of assembled housing and two identical removable units. Bottom part of device is plate 3, to which upper box that consist of 3 housing walls is screwed.

On devices removable basis 4 special changs are attached 1, 5. For easement of part fixing, changs are made so in lose position they make opening 0,3mm bigger than part outer diameter.

After parts are inserted opening is removed with the help of nine chocks 6, that are moved up by means of eccentric 7 that is controlled by handle 8.

Final fixing of parts is made with help of devices removable part fixing with swinging lip 9 and screw tightener 10 that is controlled by handle 11. Only small turn of handle 11 is needed for tightening.

In the picture I attached there is shown a device that I should design, maybe improve it, but the problem is that a drawing is a bit unclear and I can't fully understand it so I couldn't make 3D model. In the bottom of drawing it is a drawing of part that has to be milled.

Maybe you know where I could find a different design (not so ancient) of such holder that would be suitable for given parts and be easier to understand. Or if not could you help me understand this one drawing and help me make 3D model of such device.

Following is translation from Russian language. I am not very good at Russian, nor am I native English speaker so this translation might be hard to understand.

Description of drawing:

This device is for milling groves on 10 cilinder shaped parts at the same time.

Datum of part is established by outer surface that is inserted into 10 special changs (not sure how to translate the word) holes 1. These changs also are device fixing elements. As an extra datum point serves support 2. Device consist of assembled housing and two identical removable units. Bottom part of device is plate 3, to which upper box that consist of 3 housing walls is screwed.

On devices removable basis 4 special changs are attached 1, 5. For easement of part fixing, changs are made so in lose position they make opening 0,3mm bigger than part outer diameter.

After parts are inserted opening is removed with the help of nine chocks 6, that are moved up by means of eccentric 7 that is controlled by handle 8.

Final fixing of parts is made with help of devices removable part fixing with swinging lip 9 and screw tightener 10 that is controlled by handle 11. Only small turn of handle 11 is needed for tightening.