- #1

Nikhil N

- 81

- 2

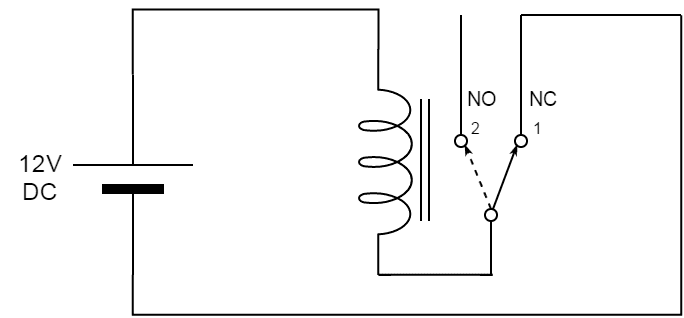

I am using the relay as chatter. That is I am continuously on-off the relay to produce bursts. I am using 12V DC relay. I got voltage upto ~120V while it is switching very fast initially. Now I am not getting high voltage while switching. I am getting only ~10V. What may be the reason? Is it problem of coil inside the relay?

I am measuring the voltage between the point of coil where +ve of battery is connected and the NO terminal.

I am measuring the voltage between the point of coil where +ve of battery is connected and the NO terminal.