- #1

Name:riley

- 4

- 0

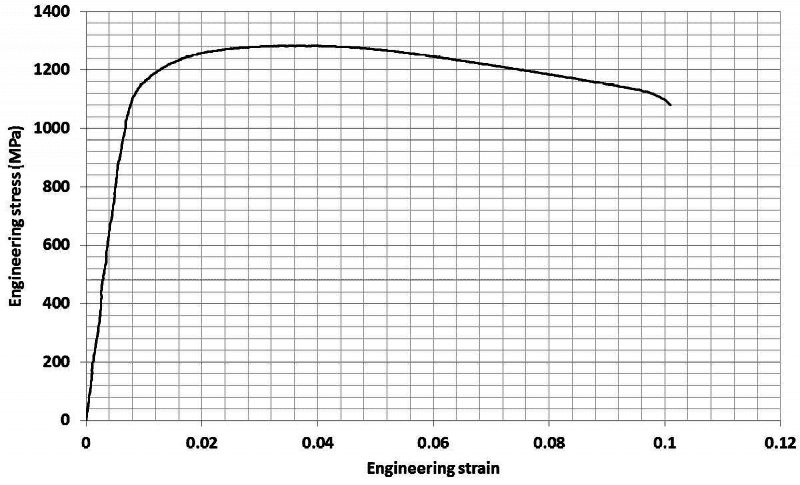

Hello I'm having trouble wrapping my head around finding things from stress strain curvesI need to find:

Elastic modulus (Young’s modulus)

•Yield strength

•Tensile strength

•Uniform and total elongation (ductility)

elastic modulus I think is 1240/0.02 = 62000

but I'm unsure of how to find the others.

Thank you to anyone who helps out.

Elastic modulus (Young’s modulus)

•Yield strength

•Tensile strength

•Uniform and total elongation (ductility)

elastic modulus I think is 1240/0.02 = 62000

but I'm unsure of how to find the others.

Thank you to anyone who helps out.