- #1

Hondaboi1729

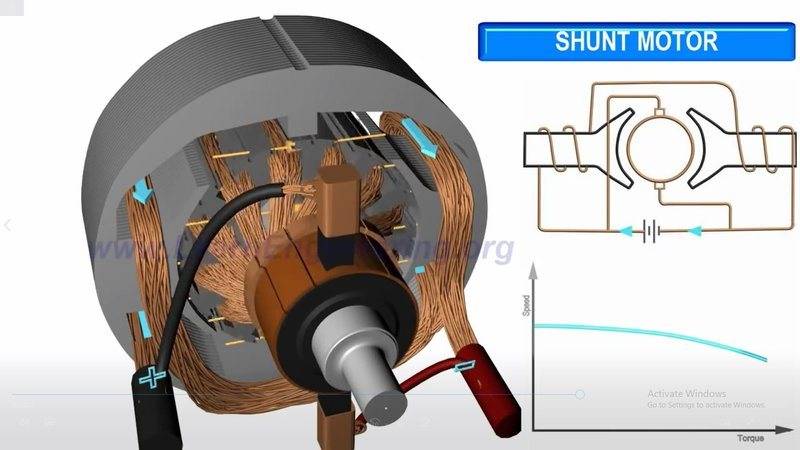

Hi in every theoretical explanation of any kind of DC motor there's always a split ring commutator and two brushes like in the following pic

then when it comes to my motorbike/car starter motor rebuild the real thing in practice is different- see the following pic with four carbon brushes- two of them have insulation on the wires and the other two you see bare wire... what are they for- no one ever tries to give a theoretical explanation of what the real thing is in practice- and what use is the pure theory if that's not what I'm going to actually see when I'm working with these things- it's really frustrating me.

there's no absolutely zero mention of any two more brushes in any explanation of any DC motor.

also do starter motors work with a field coil or a permanent magnet. if one where is it in a pic, if the other where is it in a pic...

then when it comes to my motorbike/car starter motor rebuild the real thing in practice is different- see the following pic with four carbon brushes- two of them have insulation on the wires and the other two you see bare wire... what are they for- no one ever tries to give a theoretical explanation of what the real thing is in practice- and what use is the pure theory if that's not what I'm going to actually see when I'm working with these things- it's really frustrating me.

there's no absolutely zero mention of any two more brushes in any explanation of any DC motor.

also do starter motors work with a field coil or a permanent magnet. if one where is it in a pic, if the other where is it in a pic...

Last edited by a moderator: