- #1

WilburWonka

- 2

- 3

- TL;DR Summary

- "DIY" Air filters have 2 widespread design types, Filter slapped on box-fan or 4 filters and a box fan joined to form a cube(the latter is known as Comparetto cube). The Comparetto gives a better airflow. I'd like to know if the venturi effect has anything to do with the superior airflow performance of this air cleaner type.

Typical box fan+air filter setups use axial consumer-grade fans designed for providing maximum air flow at low power consumption. These fans do not provide sufficient air flow at the high static pressure requirements typical of air filters. The air filters DIYers use are high Merv(e.g Merv 13) furnace filters, and those are meant to be paired with centrifugal fans, which deliver more air flow under high static pressure. As a result the filter-on-a-fan setup suffers from low air flow and potentially causes the fan to overheat. Here is an example of the filter-on-a-fan setup:

An improvement on this is the Comparetto cube:

The increase of the number of air filters leads to an increase in the air flow, and even despite the use of axial fans to move air through these filters, these air cleaners have airflow delivery comparable to that which the fan manufacturer specified. Fan manufacturers for these box fans typically state their fans air flow(CFM) for conditions in which no resistance was placed in the path of the fan. I take it to mean then that if an anemometer aided calculation for the air cleaner showed airflow in the same range as the box fans label air flow, then the resistance(static pressure drop) from the air filters was minimal from the Comparetto cube(at least while the filters are still new).

This can easily be attributed to the 4x increase in filter surface area, which means less CFM is passing through each filter so the resistance is less.

Have a look at this graph here relating filter face velocity to the resistance for an air filter( Specifically, these ones). I would hypothesize that the resistances from the air filters would add up something similar(not necessarily same) to resistance of resistors in a parallel circuit, so that the total resistance at a given air flow is lower than the resistance for each individual air filter. The total resistance-airflow graph of the filters would be flatter and therefore its intersection with the fan curve of the axial box-fans would be at a higher airflow.

(Here is a page explaining how that works: Skip to figure 6 for explanation. I'll also post the relevant image:)

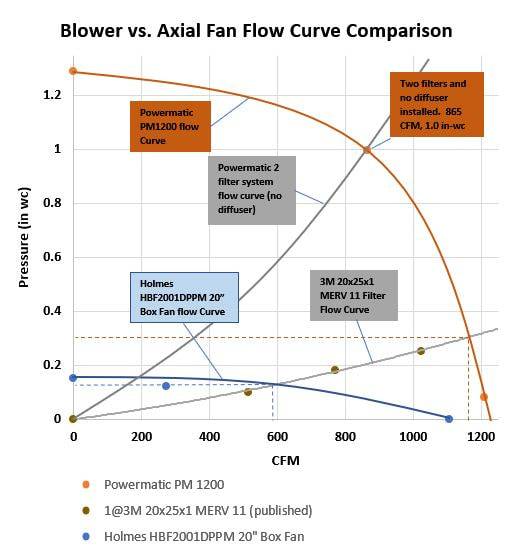

The point where the filters Resistance-Airflow curve(grey), intersects with a fans (static)Pressure-airflow curve(blue line is an axial fan, Orange line uses a centrifugal fan), gives the CFM the air cleaner will have(while the filter is still new at least).

Problem is: while all this is happening, the Comparetto cube doesn't just increase the filter mediums surface area, it seems to me, it is also increasing the cross sectional area the fluid(air) is passing through(4 times as large as the filter-on-box-fan setup). It seems to me that compared to the filter-on-box-fan setup, the air velocity is 4 times lower and the air pressure is four times higher at the Comparetto cubes filters' interfaces(Venturi effect). I'm not versed in fluid mechanics so I can't say if Bernoulli's equation applies like that in this 'system'. Is this so?

If they do, I'd think the increase in air pressure makes it easier for the filtered air to get through the air filters, so the air flow of the air cleaner is even more. In this case I'd like to know how to identify and maybe even calculate how much of that sweet CFM is a result of the Venturi effect and how much is a result of the decreased resistance due to more air filters.

An improvement on this is the Comparetto cube:

The increase of the number of air filters leads to an increase in the air flow, and even despite the use of axial fans to move air through these filters, these air cleaners have airflow delivery comparable to that which the fan manufacturer specified. Fan manufacturers for these box fans typically state their fans air flow(CFM) for conditions in which no resistance was placed in the path of the fan. I take it to mean then that if an anemometer aided calculation for the air cleaner showed airflow in the same range as the box fans label air flow, then the resistance(static pressure drop) from the air filters was minimal from the Comparetto cube(at least while the filters are still new).

This can easily be attributed to the 4x increase in filter surface area, which means less CFM is passing through each filter so the resistance is less.

Have a look at this graph here relating filter face velocity to the resistance for an air filter( Specifically, these ones). I would hypothesize that the resistances from the air filters would add up something similar(not necessarily same) to resistance of resistors in a parallel circuit, so that the total resistance at a given air flow is lower than the resistance for each individual air filter. The total resistance-airflow graph of the filters would be flatter and therefore its intersection with the fan curve of the axial box-fans would be at a higher airflow.

(Here is a page explaining how that works: Skip to figure 6 for explanation. I'll also post the relevant image:)

The point where the filters Resistance-Airflow curve(grey), intersects with a fans (static)Pressure-airflow curve(blue line is an axial fan, Orange line uses a centrifugal fan), gives the CFM the air cleaner will have(while the filter is still new at least).

Problem is: while all this is happening, the Comparetto cube doesn't just increase the filter mediums surface area, it seems to me, it is also increasing the cross sectional area the fluid(air) is passing through(4 times as large as the filter-on-box-fan setup). It seems to me that compared to the filter-on-box-fan setup, the air velocity is 4 times lower and the air pressure is four times higher at the Comparetto cubes filters' interfaces(Venturi effect). I'm not versed in fluid mechanics so I can't say if Bernoulli's equation applies like that in this 'system'. Is this so?

If they do, I'd think the increase in air pressure makes it easier for the filtered air to get through the air filters, so the air flow of the air cleaner is even more. In this case I'd like to know how to identify and maybe even calculate how much of that sweet CFM is a result of the Venturi effect and how much is a result of the decreased resistance due to more air filters.