- #1

Big Tommy C

- 16

- 6

Hello, Hope everyone is doing well.

I have a personal project I am working on and am trying to figure out the nature of the hydraulic system. I want to size a valve to the system properly and have been reading a lot about the Cv value. I don't fully understand how to implement this value into useful information and it may not be relevant to my application because this is a static value, but I will provide an example of my systems operating conditions.

The system will charge to a known value say 3000psi before the cycle begins. Each cycle will have to reach this value before it is allowed to begin.

The system also contains a hydraulic accumulator, I know the discharge volume per 100 psi drop in pressure.

When the cycle begins a logic valve will be vented and open, I can dictate the speed at which it opens but cannot easily meter the valve, it will switch to the fully open position, I can simply delay the open rate.

As the actuator moves the system pressure will drop quickly, the pump will not provide anywhere near enough flow to sustain pressure the accumulator will effectively be the prime mover during this period.

The actuator must be accelerated to a known final velocity over a known displacement, this also provides a known volume of oil that will need to be displaced.

I can also calculate the pressure drop on the supply side of the system if I displace the actuator over a known time.

I am trying to determine what size valve I should use to give me the flow I need to achieve the acceleration required.

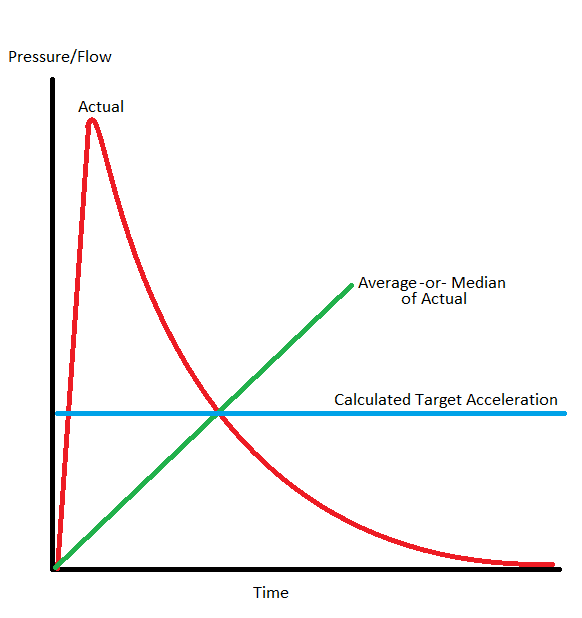

I know as my pressure drops my flow will be equally effected, and I know the pressure differential on the valve will also effect flow. Any change in flow will change my rate of acceleration. So I am kinda stuck at this point I think I need a pressure differential to determine a valve size?

I think that ultimately since my acceleration will never be constant I will have to start with a higher acceleration and end with a lower acceleration to get and average acceleration that will provide my final velocity?

Example

I have a personal project I am working on and am trying to figure out the nature of the hydraulic system. I want to size a valve to the system properly and have been reading a lot about the Cv value. I don't fully understand how to implement this value into useful information and it may not be relevant to my application because this is a static value, but I will provide an example of my systems operating conditions.

The system will charge to a known value say 3000psi before the cycle begins. Each cycle will have to reach this value before it is allowed to begin.

The system also contains a hydraulic accumulator, I know the discharge volume per 100 psi drop in pressure.

When the cycle begins a logic valve will be vented and open, I can dictate the speed at which it opens but cannot easily meter the valve, it will switch to the fully open position, I can simply delay the open rate.

As the actuator moves the system pressure will drop quickly, the pump will not provide anywhere near enough flow to sustain pressure the accumulator will effectively be the prime mover during this period.

The actuator must be accelerated to a known final velocity over a known displacement, this also provides a known volume of oil that will need to be displaced.

I can also calculate the pressure drop on the supply side of the system if I displace the actuator over a known time.

I am trying to determine what size valve I should use to give me the flow I need to achieve the acceleration required.

I know as my pressure drops my flow will be equally effected, and I know the pressure differential on the valve will also effect flow. Any change in flow will change my rate of acceleration. So I am kinda stuck at this point I think I need a pressure differential to determine a valve size?

I think that ultimately since my acceleration will never be constant I will have to start with a higher acceleration and end with a lower acceleration to get and average acceleration that will provide my final velocity?

Example