- #1

Saladsamurai

- 3,020

- 7

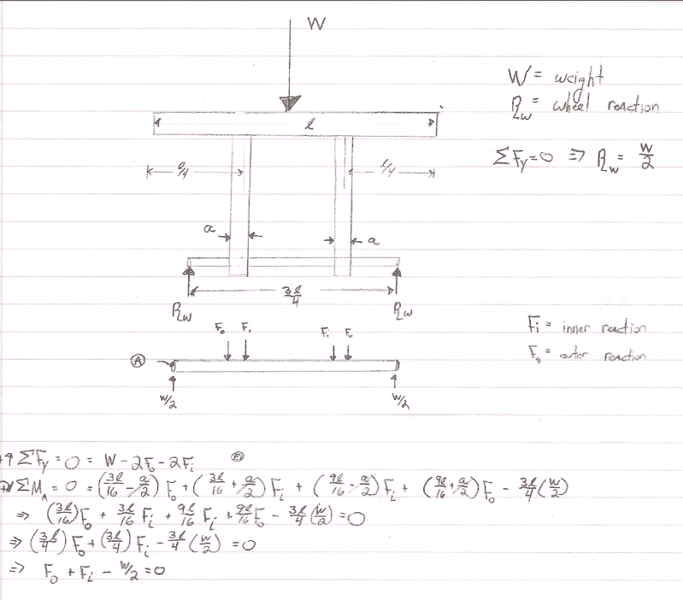

Okay, so I am trying to analyze the reaction forces that are induced by a loading on this axle.

I am running into a problem because my sum of moments equation is not independent of my force summation.

That was due to a poor choice of a point to sum the moments about So I could do it again about another point, but before I do I was wondering. Is there already a common convention on how the loading will be distributed to the reaction forces on the "strut" in the diagram Fo and Fi?

So I could do it again about another point, but before I do I was wondering. Is there already a common convention on how the loading will be distributed to the reaction forces on the "strut" in the diagram Fo and Fi?

Thanks?

I am running into a problem because my sum of moments equation is not independent of my force summation.

That was due to a poor choice of a point to sum the moments about

So I could do it again about another point, but before I do I was wondering. Is there already a common convention on how the loading will be distributed to the reaction forces on the "strut" in the diagram Fo and Fi?

So I could do it again about another point, but before I do I was wondering. Is there already a common convention on how the loading will be distributed to the reaction forces on the "strut" in the diagram Fo and Fi?Thanks?