- #1

Master1022

- 611

- 117

- Homework Statement

- A design of an axial flow gas turbine stage is conducted for the following parameters at the mean radius:

Stage inlet stagnation conditions: ## p_{01} ## = 4 bar, ## T_{01} ## = 900 K

Flow angle at stator exit = 65 degrees

Stage reaction = 0.5

Flow coefficient = ##C_x ⁄ U ## = 0.6

Static pressure at stage exit: ##p_3## = 2

Total-to-static efficiency: ##\eta_{ts} ## = 0.85

Assuming the constant axial velocity across the stage, and air as working fluid (##c_p## = 1005 J/kgK, ##R## = 287 J/kgK), determine:

i) the specific work done by the gas,

ii) the blade speed,

iii) the static temperature at the stage exit.

- Relevant Equations

- Euler work equation

Hi,

I was attempting the following turbo machinery problem and am getting quite stuck on the first part of the question. The question is:

A design of an axial flow gas turbine stage is conducted for the following parameters at the mean radius:

Stage inlet stagnation conditions: ## p_{01} ## = 4 bar, ## T_{01} ## = 900 K

Flow angle at stator exit = 65 degrees

Stage reaction = 0.5

Flow coefficient = ##\phi = C_x ⁄ U ## = 0.6

Static pressure at stage exit: ##p_3## = 2

Total-to-static efficiency: ##\eta_{ts} ## = 0.85

Assuming the constant axial velocity across the stage, and air as working fluid (##c_p## = 1005 J/kgK, ##R## = 287 J/kgK), determine:

i) the specific work done by the gas,

ii) the blade speed,

iii) the static temperature at the stage exit.

Attempt:

(i) the specific work done by the gas

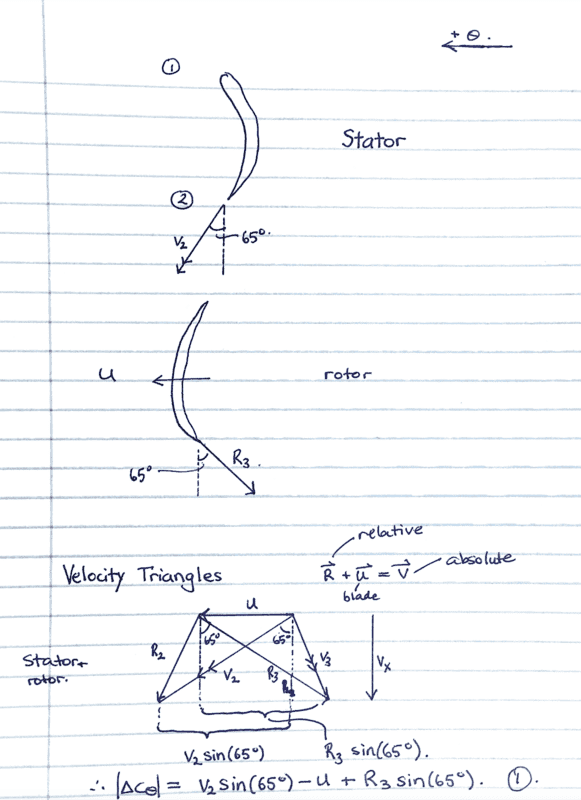

I am not sure how to make progress in this area. From looking at the data given in the question, I am trying to extract the useful information and draw the following velocity triangles:

From there, we are told that the axial velocity is constant across the stage and can thus write:

[tex] V_2 cos(65) = R_3 cos(65) = V_x \rightarrow V_2 = R_3 = V_x = 0.6 U [/tex]

Substituting this into equation (1) from the picture (bottom of page), which is the magnitude of the change of the whirl velocity then turns it into:

[tex] |\Delta c_{\theta}| = 0.6Usin(65) - U + 0.6Usin(65) [/tex]

[tex] |\Delta c_{\theta}| = U(1.2sin(65) - 1) [/tex]

Thus from the Euler work equation:

[tex] \frac{P}{\dot m} = \Delta U c_{\theta} = U^2 (1.2sin(65) - 1) [/tex]

However, I think this will only be useful for the second part of the question...

Returning back to trying to find the work, I was thinking that perhaps I could go down the route of:

1. Use relation between stagnation enthalpy and stagnation pressure to get ## \Delta h_0 ## and incorporate the total to static efficiency ##\eta_{ts} ##

2. Using SFEE to relate specific work and change in stagnation enthalpy

So this method would start with the thermodynamic relation: ## T_0 ds = dh_0 - dp_0 / \rho ##. We can calculate the change for the isentropic case first, thus ## ds = 0##, which yields the equation:

[tex] dh_0 = dp_0 / \rho \rightarrow \rho \Delta h_0 = \Delta p_0 [/tex]

However, this makes the assumption that the density is constant which perhaps isn't correct to assume... Then we could assume that the stagnation pressure across the stator such that ## p_{01} = p_{02} ## = 4 bar. Then perhaps I can use:

[tex] p_{01} - p_{02} = (p_1 - p_2) + \frac{1}{2}(v_{2} ^2 - v_{1} ^ 2) [/tex]

I am not really sure if I am missing out a formula or concept that would help me here. Any guidance would be really appreciated.

I was attempting the following turbo machinery problem and am getting quite stuck on the first part of the question. The question is:

A design of an axial flow gas turbine stage is conducted for the following parameters at the mean radius:

Stage inlet stagnation conditions: ## p_{01} ## = 4 bar, ## T_{01} ## = 900 K

Flow angle at stator exit = 65 degrees

Stage reaction = 0.5

Flow coefficient = ##\phi = C_x ⁄ U ## = 0.6

Static pressure at stage exit: ##p_3## = 2

Total-to-static efficiency: ##\eta_{ts} ## = 0.85

Assuming the constant axial velocity across the stage, and air as working fluid (##c_p## = 1005 J/kgK, ##R## = 287 J/kgK), determine:

i) the specific work done by the gas,

ii) the blade speed,

iii) the static temperature at the stage exit.

Attempt:

(i) the specific work done by the gas

I am not sure how to make progress in this area. From looking at the data given in the question, I am trying to extract the useful information and draw the following velocity triangles:

From there, we are told that the axial velocity is constant across the stage and can thus write:

[tex] V_2 cos(65) = R_3 cos(65) = V_x \rightarrow V_2 = R_3 = V_x = 0.6 U [/tex]

Substituting this into equation (1) from the picture (bottom of page), which is the magnitude of the change of the whirl velocity then turns it into:

[tex] |\Delta c_{\theta}| = 0.6Usin(65) - U + 0.6Usin(65) [/tex]

[tex] |\Delta c_{\theta}| = U(1.2sin(65) - 1) [/tex]

Thus from the Euler work equation:

[tex] \frac{P}{\dot m} = \Delta U c_{\theta} = U^2 (1.2sin(65) - 1) [/tex]

However, I think this will only be useful for the second part of the question...

Returning back to trying to find the work, I was thinking that perhaps I could go down the route of:

1. Use relation between stagnation enthalpy and stagnation pressure to get ## \Delta h_0 ## and incorporate the total to static efficiency ##\eta_{ts} ##

2. Using SFEE to relate specific work and change in stagnation enthalpy

So this method would start with the thermodynamic relation: ## T_0 ds = dh_0 - dp_0 / \rho ##. We can calculate the change for the isentropic case first, thus ## ds = 0##, which yields the equation:

[tex] dh_0 = dp_0 / \rho \rightarrow \rho \Delta h_0 = \Delta p_0 [/tex]

However, this makes the assumption that the density is constant which perhaps isn't correct to assume... Then we could assume that the stagnation pressure across the stator such that ## p_{01} = p_{02} ## = 4 bar. Then perhaps I can use:

[tex] p_{01} - p_{02} = (p_1 - p_2) + \frac{1}{2}(v_{2} ^2 - v_{1} ^ 2) [/tex]

I am not really sure if I am missing out a formula or concept that would help me here. Any guidance would be really appreciated.