- #1

Davide Fabri

- 1

- 0

Goodmornig everybody,

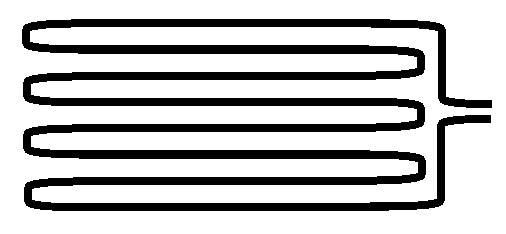

I'm working on the design of a power converter for high frequency induction heating. The induction coil should be a flat spiral (pancake) with a rectangular shape, but my customer would like to design it as shown in the following picture. I think it will not work because that way magnetic field lines are canceled. What do you think ?

Thank you.

Davide

I'm working on the design of a power converter for high frequency induction heating. The induction coil should be a flat spiral (pancake) with a rectangular shape, but my customer would like to design it as shown in the following picture. I think it will not work because that way magnetic field lines are canceled. What do you think ?

Thank you.

Davide