- #1

person123

- 328

- 52

- TL;DR Summary

- I want to check my understanding of what the lines of stress shown in a material means; I'm also curious if there's a relation between them and scalar fields which satisfy Laplace's equation, like streamlines for a fluid.

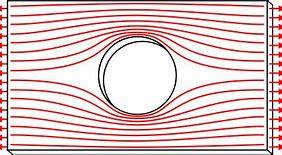

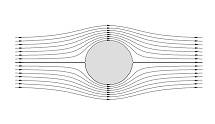

I was initially curious by the fact that streamlines around a circle appear the same as the lines of stress around a hole:

I understand that streamlines are the contour lines of the stream function ##\psi## which satisfies the Laplace equation. I was wondering there is a related function for the lines of stress.

I want to make sure I understand what the lines of stress in a solid material (first image) represent. This is my understanding:

I think there are actually two orthogonal lines of stress in a material. I'm guessing that at any point in the material, the orientation of the lines are the orientation of the principal stresses. I believe that the closer the lines are together the greater the stress or ##\frac{\partial \phi}{\partial x}=\sigma_x##. However, I am not sure where to go from here to show whether the function satisfies Laplace's equation.

I understand that streamlines are the contour lines of the stream function ##\psi## which satisfies the Laplace equation. I was wondering there is a related function for the lines of stress.

I want to make sure I understand what the lines of stress in a solid material (first image) represent. This is my understanding:

I think there are actually two orthogonal lines of stress in a material. I'm guessing that at any point in the material, the orientation of the lines are the orientation of the principal stresses. I believe that the closer the lines are together the greater the stress or ##\frac{\partial \phi}{\partial x}=\sigma_x##. However, I am not sure where to go from here to show whether the function satisfies Laplace's equation.

Last edited: