- #1

guusmatijs

- 1

- 0

I am currently working on printing conducting inks. After printing and sintering the inks my goal is to measure conductivity of my printed patterns. Therefore I want to create 4 strips of aluminium using deposition on my substrates before I print my ink.

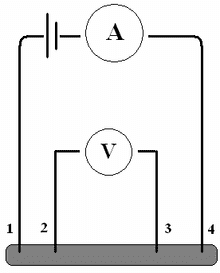

I want to use these strips to perform a four terminal sensing measurement on the conductivity of my printed ink strips. In most documentation I find that the distance between points 1-2 and 3-4 in the image below is smaller than the distance between points 2-3.

However the mask I created for depositing the aluminium on my substrates leaves four strips of aluminium with equal distances (see image below) 10 mm from center to center.

[PLAIN]http://image.bayimg.com/hapbaaach.jpg

the strips of aluminium left on the substrate will have a width of 1.5 mm.

The actual question is whether I can use R=U/I, simply ohms law, or whether I need to use a correction factor like discussed in Haldor (please refer to attachment), R=G * U/I.

The strips I will be printing across the aluminium strips will have a width of 100-1000[tex]\mu[/tex]m depending on my printing settings. the thickness of my print will be approx 10 times smaller.

I hope I cleared out my question, If you need anything else please let me know.

Thank you :)

Attachment: Haldor

http://dl.dropbox.com/u/1073056/Handige%20eBooks/Haldor%20weerstandsbepaling.pdf"

I want to use these strips to perform a four terminal sensing measurement on the conductivity of my printed ink strips. In most documentation I find that the distance between points 1-2 and 3-4 in the image below is smaller than the distance between points 2-3.

However the mask I created for depositing the aluminium on my substrates leaves four strips of aluminium with equal distances (see image below) 10 mm from center to center.

[PLAIN]http://image.bayimg.com/hapbaaach.jpg

the strips of aluminium left on the substrate will have a width of 1.5 mm.

The actual question is whether I can use R=U/I, simply ohms law, or whether I need to use a correction factor like discussed in Haldor (please refer to attachment), R=G * U/I.

The strips I will be printing across the aluminium strips will have a width of 100-1000[tex]\mu[/tex]m depending on my printing settings. the thickness of my print will be approx 10 times smaller.

I hope I cleared out my question, If you need anything else please let me know.

Thank you :)

Attachment: Haldor

http://dl.dropbox.com/u/1073056/Handige%20eBooks/Haldor%20weerstandsbepaling.pdf"

Last edited by a moderator: