- #1

Bakez

- 11

- 0

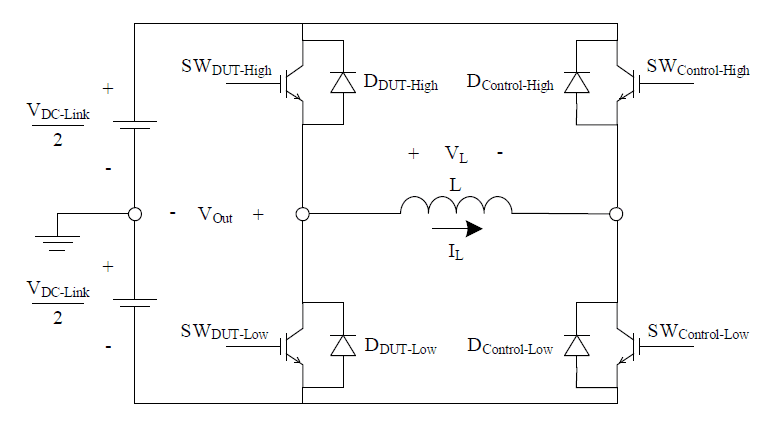

I have a single phase DC-AC inverter (or H-Bridge) with an inductive load

I want to design a controller that controls the PWM signals to the control side switches that will ensure there is a sinusoidal current through the load. I need to use PI control and implement into a DSP so it has to be a discrete (z-domain).

I am really struggling with this. I have an understanding of how a h-bridge works but little control knowledge. I know the transfer function of the inductive load is:[itex]\frac{1}{sL + R}[/itex]. and I know I will have a reference current (which I want to the output through the load) and a measured current that I will feedback into the start to calculate the error.

If anyone has any tips or tutorials in this I would greatly appreciate the help

I want to design a controller that controls the PWM signals to the control side switches that will ensure there is a sinusoidal current through the load. I need to use PI control and implement into a DSP so it has to be a discrete (z-domain).

I am really struggling with this. I have an understanding of how a h-bridge works but little control knowledge. I know the transfer function of the inductive load is:[itex]\frac{1}{sL + R}[/itex]. and I know I will have a reference current (which I want to the output through the load) and a measured current that I will feedback into the start to calculate the error.

If anyone has any tips or tutorials in this I would greatly appreciate the help