- #1

Nik_Barbour

- 2

- 0

Hi,

I was wondering if I could ask for some advice.

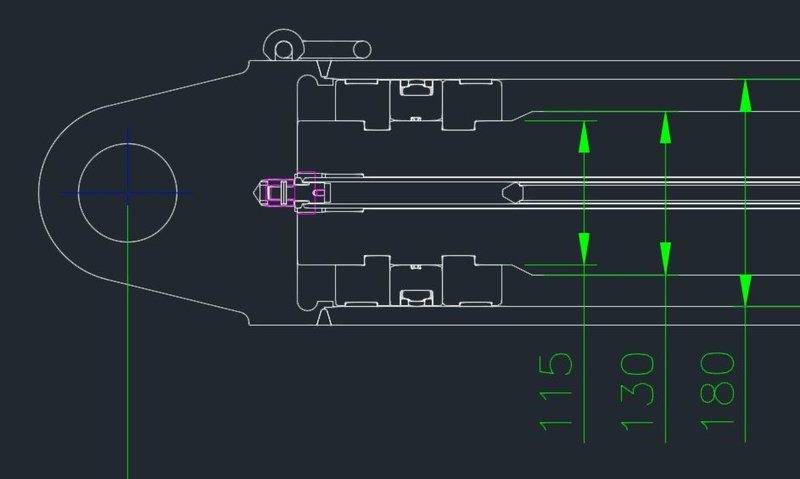

I'm was calculating the Annulus force that a hydraulic cylinder could generate that I've been asked to do some work on, however this particular ram is a little unusual in that it had a split rear piston and necks down to a smaller diameter than the rod to which it attaches. (see attached pic)

I was happily calculating retract force as (Ø180 bore area - Ø115 bore area) x pressure when the guy I was working for said no. The annulus force is the (cyl ID area - rod area) so [Ø180 bore area - Ø130 bore area].

Imagining the hydraulic cyl isn't in its fully closed position as shown, but traveling in its closing direction, I was thinking hydraulic fluid transmits its pressure to the surface area it contacts, not the area it passes through.

Just wondered if anyone could confirm which is correct for my own personal interest.

Thanks in advance for any advice given,

I hope my question makes sense.

I was wondering if I could ask for some advice.

I'm was calculating the Annulus force that a hydraulic cylinder could generate that I've been asked to do some work on, however this particular ram is a little unusual in that it had a split rear piston and necks down to a smaller diameter than the rod to which it attaches. (see attached pic)

I was happily calculating retract force as (Ø180 bore area - Ø115 bore area) x pressure when the guy I was working for said no. The annulus force is the (cyl ID area - rod area) so [Ø180 bore area - Ø130 bore area].

Imagining the hydraulic cyl isn't in its fully closed position as shown, but traveling in its closing direction, I was thinking hydraulic fluid transmits its pressure to the surface area it contacts, not the area it passes through.

Just wondered if anyone could confirm which is correct for my own personal interest.

Thanks in advance for any advice given,

I hope my question makes sense.